Certification:

12

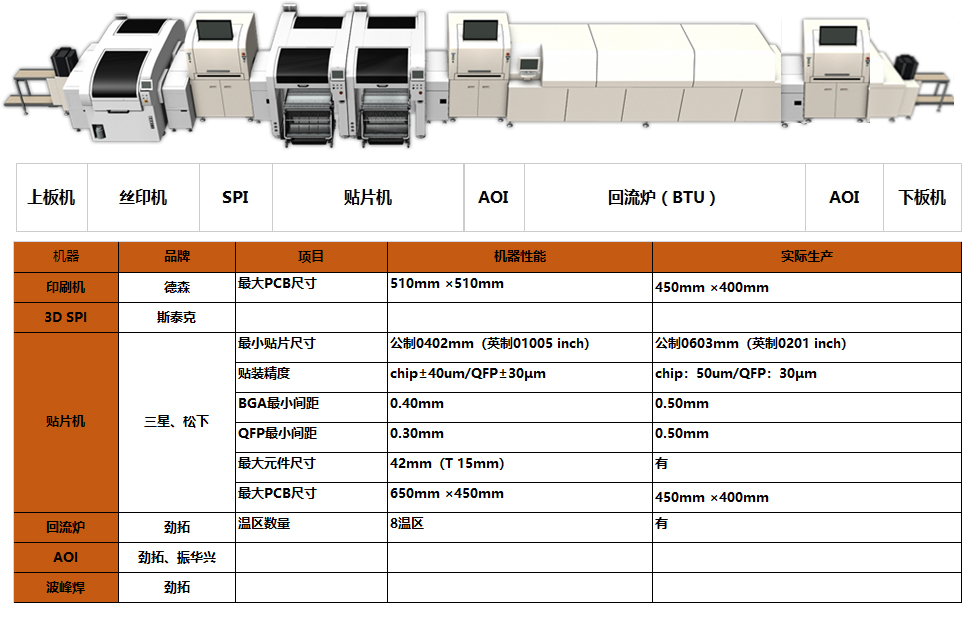

High-tech SMT production line

12

wave soldering

10

Conformal coating

3

Workshop

EMS manufacturing

The company has brand-new production equipment, excellent management and technical team, fast response speed and good service awareness, and can provide customers with SMT, DIP, ICT testing, FT testing, conformal paint coating, machine assembly, testing, Aging and other full-process services.There are 12 SMT production lines, with a daily mounting capacity of 12 million components, which can be expanded to 16, with a daily mounting capacity of 16 million components.

There are 12 DIP peak production lines, with a daily plug-in production capacity of 1.2 million components, which can be expanded to 16, with a daily plug-in production capacity of 1.6 million components.

There are 10 selective automatic spraying production lines for conformal paint, which can be expanded to 12 later.

There are 10 complete machine assembly lines, and the daily production capacity of 15kw charging pile module assembly can reach 2,000.

Each process can process 450mm*600mm large-size veneer.

Our business

Provide SMT, DIP, ICT testing, FT testing, conformal paint coating, machine assembly, testing, aging, packaging full-process services.

ICT/FT

Conformal coating

Assembly

Test/Aging

Package

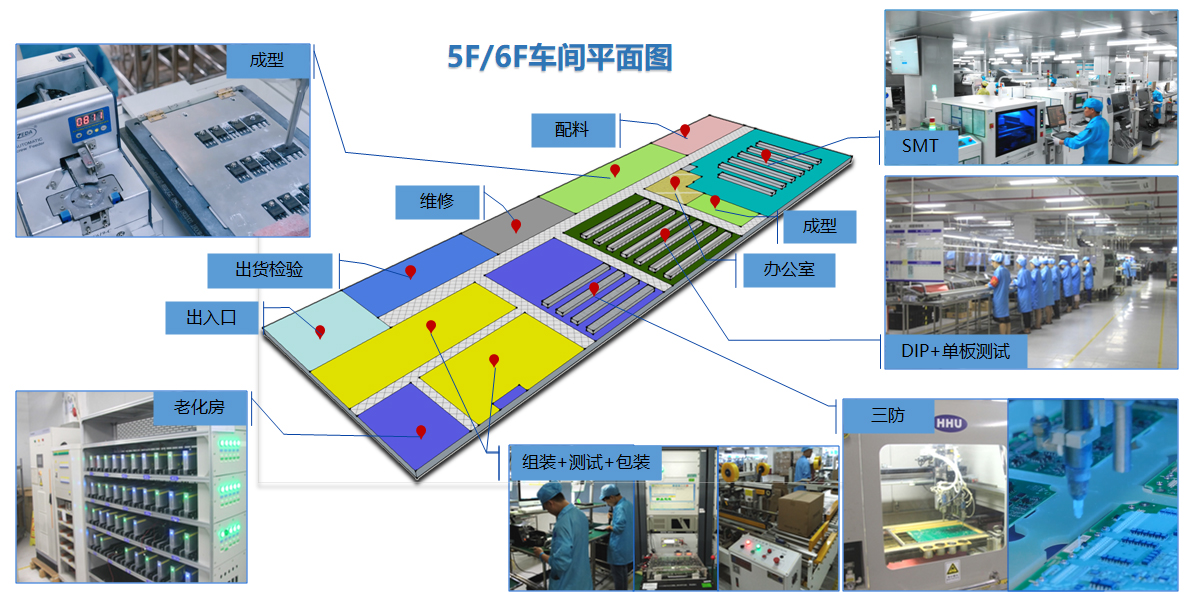

Workshop floor plan

he 3 independent workshops are divided into leaded, lead-free, and automotive products. The workshops are all planned and laid out in accordance with the "one-stroke, one-flow" concept of lean production, from smt→dip→testing→three-proofing→assembly→aging→packaging The process is completed on one floor, the logistics is smooth and reasonable, and the personnel, materials, products and equipment are in a good environment with controllable temperature and humidity. The workshop floor adopts PVC anti-static floor.

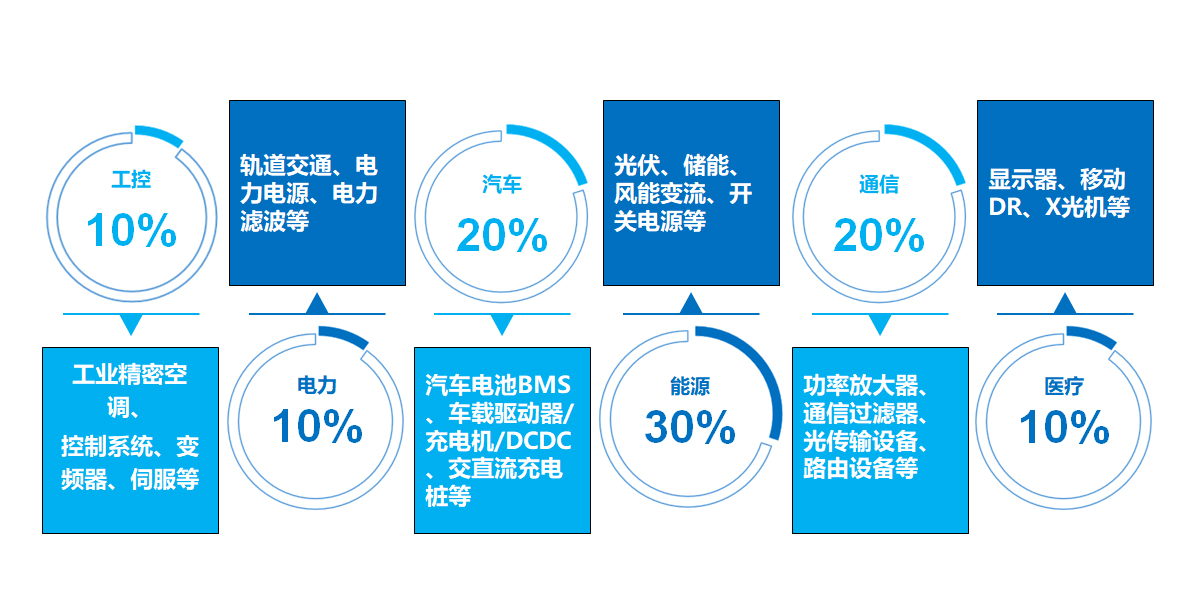

Diversified industry customers

The company is committed to providing professional EMS electronic precision manufacturing and OEM services for electric vehicles, new energy, rail transit, military industry, medical treatment, electric power, automation, power supply, communication and other industrial customers.

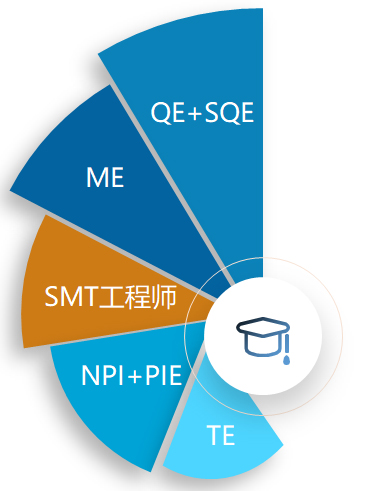

Technical team

Experienced technical team, mature and stable front-line employees ensure the production of high-quality products.

-

1. The average service life of engineering and technical personnel is 3-5 years.

-

2. More than 50% of the skilled employees in the production workshop have been employed for 2-3 years

- 3. The age group of 20-35 in the production workshop accounts for more than 75%